Once I knew Ford was producing a new Ford GT (in March of 2002) I followed the car’s progress very closely. I’d already let my Ford contacts know I wanted a GT, but there was no guarantee I’d have any better shot at one than the thousands of other car fanatics chomping at the bit. Actually, despite the car’s stunning looks and unique mid-engine V8 design I was surprised how many people didn’t know the Ford GT was coming. But that would change soon…

In the meantime I kept in close contact with my friends at Ford, listening for any updates on development progress. I even flew to the Ford GT’s development center in Dearborn and interviewed several members of the design team. Here is the original text from an August 21st, 2003 story:

2005 Ford GT: Homage to Ford’s Past, Glimpse of Ford’s Future?

In the spring of 2004 Ford dealers will begin receiving their allotment of 2005 Ford GTs. The allotment wont be large; in fact, many dealers will never see a GT except in photographs. Less than half will receive one unit for the entire 2005 production run, and a tiny fraction will receive two or more. The total first year production is slated for between 1,000 and 1,500 units, which explains why most of the 3,500 Ford dealers in the U.S. will never get one in their showroom. Rumor has it that hundreds within Ford Motor Company are among the first in line to buy a GT. Right behind them are the dealer owners, many of whom have been patiently waiting for a car like the GT to fulfill their exotic-car desires desires that could never be met by a foreign nameplate like Ferrari or Porsche without bringing along unwanted political baggage.

There’s no denying the historic equity steeped in the new Ford GT. A modern-day interpretation of the GT40 that dominated Le Mans in the mid- to late 1960s, the new GT is supposed to represent not only the best of Ford’s past but also the promise of the company’s future. Automakers often refer to vehicles like this as halo cars. By themselves, they cant erase red ink or regain market share, but a halo car can improve a brands awareness and lead to increased showroom traffic. Mazdas Miata is probably one of the most effective halo cars from the last decade. Fords own Thunderbird was somewhat less successful on this front. The Thunderbird, introduced in 2002, is slated to go out of production in 2005 after three years of disappointing sales figures.

The Thunderbirds departure will leave the lions share of Ford’s branding and image efforts on the admittedly broad shoulders of its all-new 2005 GT, though the redesigned 2005 Mustang will also lend a hand. As Ford moves forward with its revival plan, and at a time when Ford needs all the brand awareness it can get, the role of the GT goes beyond feature articles in enthusiast publications and flashy appearances in one or more Hollywood productions. The money and manpower expended to bring a production version of the GT to life, a goal achieved in record-setting time, will likely serve as a testbed for future product development procedures.

To understand the justification behind the GT, as well as all that went into creating it, I spent a few days discussing the project with several team members at Fords SVT headquarters in Dearborn, Michigan. I also toured the GT plant and was walked through the process of turning a basic aluminum frame into a final production vehicle.

As impressive as Ford’s victory over Ferrari was at Le Mans in 1966, the impending battle for improved products and increased (or at least stabilized) market share has far more riding on it. Over the next three years a crucial part of this battle will be fought. Starting with the redesigned 2004 F-150, Ford is preparing an onslaught of new products between now and 2007, which also happens to be the final year of Ford GT production (at least, that’s the plan right now).

Where will the company be when the final Ford GT rolls off the assembly line at the Wixom plant in 2007? No one can say for sure, but discussions with the Ford GT team about a concept car that transformed into a production vehicle in less than 16 months provide at glimpse at future development techniques. Some of the technologies utilized in the GT program will be applied to future, volume products like the Ford Five-Hundred sedan. Beyond the technology, however, was the philosophy of bringing together a talented group of people, giving them clear goals and hard deadlines, and then getting out of the way and letting them do the work. This might be the most important piece of knowledge gleaned from creating the Ford GT.

Karl Brauer: Why did Ford Build the GT?

Tom Scarpello, SVT Marketing and Sales Manager: For a long time, for many, many years, there have been a number of people that have wanted to do a high-performance sports car — something really exotic. It was kind of conspicuous by its absence; of all the major automakers worldwide Ford didn’t have a real exotic, purpose-built sports car in its line up. There have been a number of concepts, projects like the GT90 concept that didn’t really make business sense. These concept projects — you do them for image reasons as opposed to financial reasons. You have to ask, How does this fit with what we’re trying to accomplish in the market place? A supercar or an exotic car is pretty much at odds with what the Ford brand stands for. Consequently, it never really happened. A few years ago another team pulled together and said Its time to do a supercar. And we took a different angle this time and decided to draw upon the heritage and the credibility that was established with the GT40 program. And that really was the illumination, because now you had something that made sense for the Ford brand and was credible, that was authentic, that people could relate to. And the fact that you’ve got this six-figure-priced car in the Ford line-up, well, if it’s based on the GT40 heritage than you can understand it and it makes sense. It fits.

Karl Brauer: Who is the Ford GT buyer?

Tom Scarpello, SVT Marketing and Sales Manager: It’s going to be a male in his 50s or 60s. He’s a car nut. He always loved cars his whole life. The GT is something that has some meaning to him and this is his chance to own something that he’s probably lusted after for a long time.

Jamal Hameedi, Ford GT Program Manager: I think you’ll see with this car a pretty unique mix of clientele. I think you’ll have the people who are into traditional European exotic cars. I think there will be a lot of consumers who would not traditionally buy this kind of a car but will be attracted to the statement of American engineering prowess. People who have plenty of money to buy a six-figure car but they wouldn’t necessarily go out and buy a Ferrari. That’s not their cup of tea. We talked to a lot of exotic car owners who said, “I’d love to buy an American supercar but they’re just not around. There are no American supercars so we have to go get Ferraris and Porsches. But we are so excited that finally someone is making an American supercar.

Primo Goffi, Product and Business Planning Specialist: There are a lot of people that wouldn’t give a second look to a European exotic car. An example would be somebody that could have a large collection of domestics, say, a muscle car enthusiast or a collector that may own a Shelby or even an original GT from the ’60s. A lot of people that obviously have the financial resources to purchase one but would never give a European exotic a second look. A lot of those people are clamoring for this car. You have dealer principals, quite a few of which have the financial resources to purchase a car in this arena but it wouldn’t be socially acceptable, for lack of a better term, to purchase a European exotic because they own a Ford store. So that opens up quite a large number of people who have the financial resources available and are most likely going to own one of these cars.

Karl Brauer: What is the primary competitor for the GT?

Tom Reichenbach, Vehicle Engineering Manager: We had only one target vehicle, the 360 Modena. Other cars have popped on the scene since then, but you can’t take the team and jump ship to aim at a new target. We keep our eye on them, but I haven’t seen anybody who worries me yet. It’s still the Modena, but in certain areas we want to surpass the Modena, in other areas we think Ferrari does a fantastic job. They keep finding more horsepower, but they better because we’ve got them covered.

Karl Brauer: The Japanese have a history of analyzing an existing market segment and then providing a vehicle that does everything as well or better than the existing models for a lower price. Is that what Ford is doing with the GT and the exotic car segment?

Tom Scarpello, SVT Marketing and Sales Manager: I think our GT is very, very different vehicle from a Ferrari 360. Obviously we bought one, evaluated it, took it apart and put it on the frame twister. I mean, that poor car has been through everything just so we understood where we are relative to them. Not to say that we’re going to do it the same way, but you have to understand how the other guys are approaching things. I think people will find they have extremely different characters. The GT will occupy a very unique position in terms of the overall experience it delivers. In this segment, the worst thing you can do is try to copy somebody whos already out there. No one else can out Ferrari Ferrari. No one else can out Porsche Porsche. Were Ford, here’s our heritage. Here’s what we’re going to be. And now well establish that and let other people come try to knock us off our mountain, but they can’t because no one else has the GT40, no one else has that heritage.

Kip Ewing, Prototype, Packaging, and Launch Supervisor: I think that there is certainly an expectation that Ford represents value, and that’s part of the DNA of the car. While I hate to look at it in terms of just transportation and value, we’re giving the customer an awful lot in performance and quality and details for the money and I’m very proud of what we’re putting forward. You know, Ferrari has evolved so much in quality of execution and detailing of the package in the 360 compared to the cars they used to produce and it really forced us to meet that expectation. You know it’s not 1985 anymore where you can get away with a leather-trimmed box with poor ergonomics.

Karl Brauer: You worked on the original Viper development program over 10 years ago. What is the biggest difference between that program and the GT program?

Neil Hannemann, Chief Program Engineer: The lack of CAD (computer-aided design). Literally, starting with the original drawing there was no CAD at all. And it took longer then, too. We had to design, test, redesign, whereas here we’re doing design, analyze, build. Also engine — we spun our wheels a little longer on, “Gee, twin-turbo V8? Or maybe just a carryover V8 and make it a $30,000 car.” There was a lot more of that than people realize.

Karl Brauer: The time constraints on this program were a big factor. Was there ever a point in the development process where you wondered if you could really pull it off?

Kip Ewing, Prototype, Packaging, and Launch Supervisor: I was confident the whole way. I don’t know if that was just nave arrogance speaking or what but we had such a capable team that knew how to leverage the CAD tools, and everybody was putting in the hours to make it happen. I never did have a moment where I thought we weren’t going to make it. I knew it was going to be difficult, but everybody was rising to the challenge.

Karl Brauer: What was the biggest challenge faced by the Ford GT team?

Neil Hannemann, Chief Program Engineer: I’ll answer by say timing. Trying to do all of the design in a small amount of time. One of the biggest design challenges was the window. Getting the window to roll down and make it look good. We were into brainstorming and doing out-of-the-box processes. Even Chris Theodore, he’d come in with sketches, he’d wake up at like four in the morning thinking about it. We had all these ideas about how it could move around in different ways and we finally decided, look, let’s just make the window roll down. What does it take to just make it go down, and the guys put together a concept that worked.

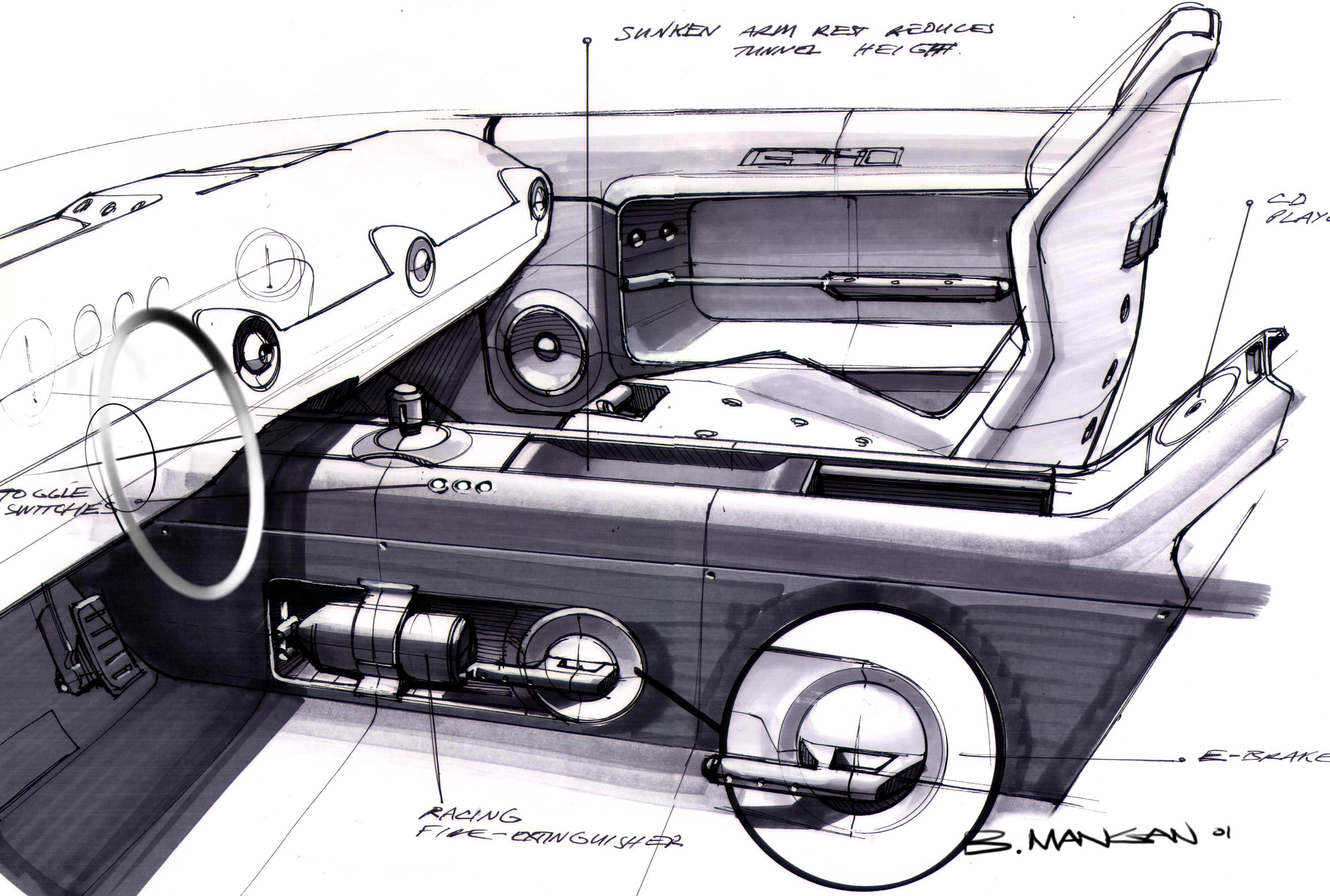

Kip Ewing, Prototype, Packaging, and Launch Supervisor: We had to design a car where the outside was developed concurrently with the interior and the mechanical package. It was very much more of an outside-in proposition so it demanded a lot of very creative engineering solutions to not compromise the occupant package, to not compromise the dynamics of the car and still keep that show car style. There was a lot of creative packaging on all of the components. This car has got about 4 inches more legroom than the show car. That was enabled by going to a forward-facing lower control arm, which pulls the lower control arm out of the driver’s feet. Going in we had the advantage of guys on the team who knew the segment and knew sports cars and had driven sports cars like this before. Myself, in a former life of being a sports car mechanic, I knew that I didn’t want to have the same problems I had in a BMW M1, Ferrari 308, etc. with a very poor pedal packaging. Knowing the problems we wanted to fix that were typical of the segment, it allowed us to drive the components and the technology to facilitate all the objectives. We wanted to not design in any compromises we wanted to really be disciplined and fix problems where they were discovered. In this car the pedals are straight ahead and you’ve got a real dead pedal. The steering wheel is straight ahead of you, properly squared up.

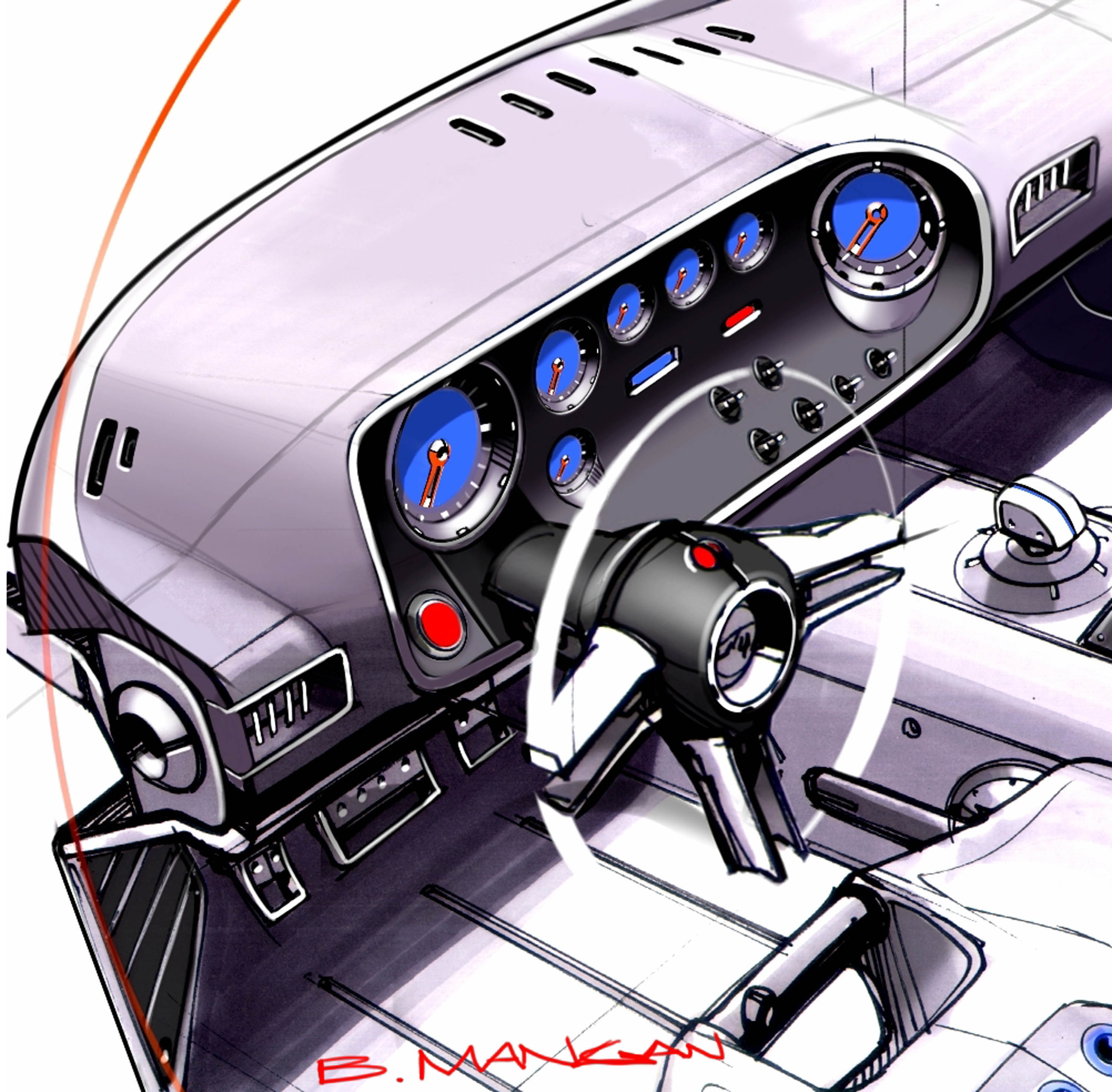

Fred Goodnow, Design Engineering Manager: Basically, we had the show car that was, on the outside, five percent feasible at most relative to the mechanics going inside. There was no AC in it, there was nothing under the skin, it was all cosmetic. Then we had to package all of the components and it’s tough, especially up in the dash area. Every square inch of this car is utilized, and it was all developed virtually in CAD. This car stretched the envelope for virtual design. When we put this car together everything was done, it was fine-tuned. It went together the first time and it works — CAD works.

Karl Brauer: What percentage of the GT comes from existing product?

Fred Goodnow, Design Engineering Manager: If I had to guess I’d have to say maybe 10 percent, but it’s stuff that makes sense. We couldn’t design a better hinge. We couldn’t design a better power window switch. The steering column, which comes from the Focus, is world-class. Richard-Parry Jones personally designed that steering column and it’s world-class. There are certain things you don’t redesign and it saves money and time. A lot of electrical components are obvious. You don’t reinvent a PCM to run an engine.

Karl Brauer: Are you happy with the final product?

Kip Ewing, Prototype, Packaging, and Launch Supervisor: (noticeable pause) I have to qualify that response. I don’t think any creative, disciplined engineer is going to be perfectly satisfied with any results, otherwise wed quit our jobs and do something else. I still say the best car I’ve ever designed in the next one. Anybody who is creative is going to look at their work very critically, and even though I look at the work critically I think that we’ve got an outstanding car and I think that it’s going to be a world-beater. People are not going to believe this car has a Ford badge on it. When you look at the performance figures for a car that was designed essentially inside of 10 months, anybody who knows anything about cars is going to appreciate what we’ve accomplished. I’m very proud of this car. I’m as proud of how the team has worked together as I am about the technical achievement.

Mark McGowan, Vehicle Dynamics Supervisor: We’ve got the stiffest frame we’ve ever made in our lives. It’s the easiest car to dial in. If you’re going out on to the track and you say, “Oh, I like a little more neutral” it’s soooo easy to do. You know, when the fundamental design is right, tuning is easy. If the design has got some problems that’s when you spend all your time trying to figure out, “How do I fix it? Where’s the problem?”

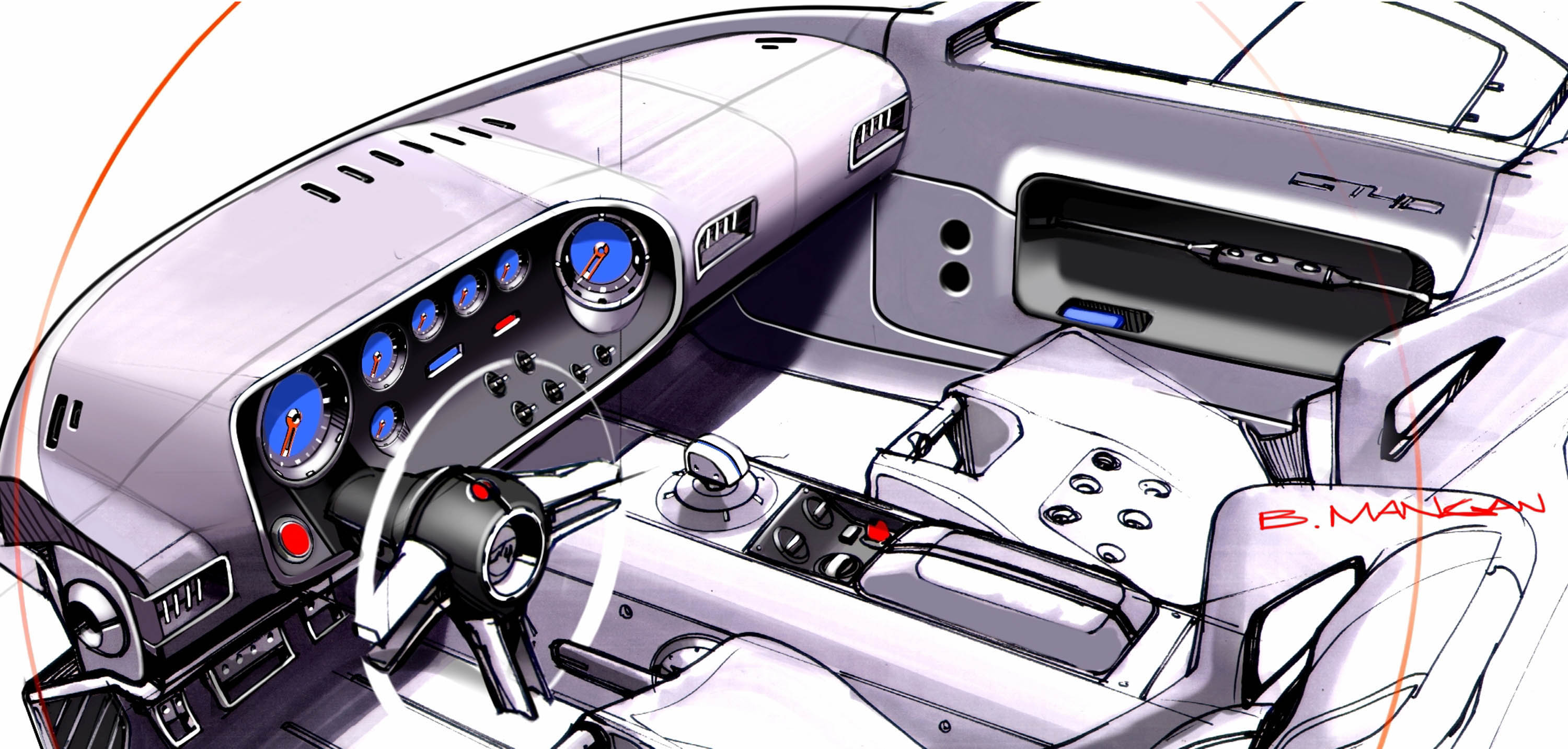

Karl Brauer: What is special about the Ford GT’s interior?

Kip Ewing, Prototype, Packaging, and Launch Supervisor: I would say all the exposed metal. That’s pretty unique in a car. Were actually, honestly bringing the structure of the car into the interior. There are a lot of cars that have tried to do that but it’s always been aesthetic only, it has been a real honest execution of bringing the structure into the interior. Typically you’ll get a lot of silver-painted plastic that is styled to look like structure but its not a load-bearing feature of the car. The interior of the GT has the actual pieces of the space frame as styled elements of the interior. You’ve got this magnesium center console cover that is actually a stressed member that contributes to the stiffness of the car. The instrument panel is a structural element of the car. The actual frame of the door is body-colored and it’s exposed on the interior, and that’s pretty unique. It’s almost motorcycle-like to see this integration of the structure and design. The grab handle of the door is actually the same piece of extrusion that we have for the A-frame over the engine. To have that as an honest part of the interior is fantastic and it’s genuine its not phony. The overall effect is pretty stunning.

Jamal Hameedi, Ford GT Program Manager: If you look at interiors, that has stereotypically been an American weakness. If you look at the Ferrari 360 it has a pretty nice interior from a fit-and-finish and materials standpoint. I haven’t seen a Gallardo in person but from the pictures I’ve seen they’ve taken that level of craftsmanship and quality of materials to another level, so the bar is rising and we understand that.

Karl Brauer: What about servicing? Is it going to be as much of a nightmare as most mid-engine cars?

Kip Ewing, Prototype, Packaging, and Launch Supervisor: No. And again, having the guys on the team who know sports cars and have worked on them and driven them and raced them. You know, we’ve all lived with the shortcomings of exotic sports cars and service was a big focus for us. A lot of us have lived with the nightmares of maintaining Ferraris and Panteras and it was all very important for us to design out the typical problems you have with this segment. We also had the advantage of a full-time Ford service engineer following the design and packaging of the car to help us stay out of those problems. Our objective is that this car, as exotic as it is, costs no more to maintain than a car like a Corvette Z06.

Karl Brauer: Will the short development time and advanced techniques used for the GT affect how other Ford products are made?

Tom Scarpello, SVT Marketing and Sales Manager: I don’t want to overstate that. Clearly its a very short timeline for a program of this magnitude and it would be nice to say that it was these world-class processes and technologies. But really what it boils down to is setting very clear objectives for a team and having a small, focused team of highly skilled people and having a lot of commitment from that team. It all starts with people. You gotta get the right people in place and make sure everyone is working toward the same goal. If you do that you’re going to be successful.

Kip Ewing, Prototype, Packaging, and Launch Supervisor: There’s been a lot said about how we leveraged technology and computer modeling but I think the biggest difference between this team and other programs is that we trusted those models much more than the normal program would. It was really driven by the constraints of time and budget to build physical properties to validate your models. I also think a lot of it is generational. Most of the guys in the program are pretty young. We’ve grown up seeing the capability of these tools. We’re familiar with them. There’s a lot more receptiveness to trusting them and using them because of our immediate comfort level.

Jamal Hameedi, Ford GT Program Manager: We’ve never done a car this quickly before from a clean sheet of paper. One of our charters is to come up with a blueprint to do this car in a specific amount of time but then also transfer lessons learned, things that worked, things that didn’t work, so that we can use the knowledge and experience gained on this program for other car programs for the future. It would almost be a crime if we just built a car and didn’t utilize lessons learned.

Karl Brauer: How was the car received at the Goodwood Festival of Speed in England? We hear Bob Lutz liked it?

Kip Ewing, Prototype, Packaging, and Launch Supervisor: He was very complimentary. He really liked it. The thing I really respect about Bob Lutz is that wherever he’s worked he’s bought other companies’ cars because he just likes cool cars. He’s got a Cobra. He’s got a Monteverdi. He’s got a Citroen. He doesn’t let the corporate politics get in the way of him just owning the car he wants. Yeah, I hope he decides to get one.

Primo Goffi, Product and Business Planning Specialist: The car was mobbed. I’m talking people 10 deep just to see the car. An amazing reaction, with a lot of people just dying to find out when it was going to arrive. And even in the company of two Enzos, two Gallardos, a Pagoni Zonda and a Carrera GT Porsche our car had more of a presence than all of those cars, and that’s a pretty big statement in that company.

Neil Hannemann, Chief Program Engineer: Lutz will buy one.

Karl Brauer: How does Ford top the GT? What’s left to do after producing something like a GT?

Tom Scarpello, SVT Marketing and Sales Manager: That’s a great question and I don’t think we know the answer yet. At least, I don’t think we’ve agreed on an answer yet. If you ask 10 different people associated with this program what they think you’ll get 10 different answers. My personal opinion is that you cant just put out a car like this and then not follow it up with something. Once you get into the segment you have to be committed to the segment for the long term.

Kip Ewing, Prototype, Packaging, and Launch Supervisor: I don’t know if we can do anything to top it. I think that we can do things that are as cool. The Ford GT represents the car for so many car guys because of its pedigree from winning Le Mans so many times. I think that there are things Ford can tap into from its history that are equally important. I would love to see a modern interpretation of the Cobra, leveraging a lot of the technology we have. Id like to see further evolution of the GT. Weve got a fantastic platform now with the car. There are all sorts of things with engine technology, body configuration and the like that we can do to carry the pace forward.

Karl Brauer: Is there any resentment within Ford about resources being spent to develop a limited production vehicle like the GT when the company has so many other serious challenges right now?

Tom Reichenbach, Vehicle Engineering Manager: No, actually just the opposite. When the people inside Ford find out what we’re getting done with such limited resources two things happen. One is that they pity us and the other is they’re worried that we’ll pull this off, and then they’ll have to do it, too. The people who don’t know anything about the project think we have the lion’s share of resources at our disposal in order to bring this project home. Nothing could be further from the truth. The casual guys, who haven’t talked to anyone on the program, think Ford has so much at stake with the GT that our guys get everything they want. Man, I can’t get anything I want. We have to do everything ourselves and when the guys inside of Ford figure this out first they pity us for about three seconds and then they say, “Holy crow, if these guys pull this off we’re screwed because they (Ford) will want to run all the projects like this”. We’re taking a five-year program and turning it into two years.

Karl Brauer: What do you see as the greatest benefit to the Ford Motor Company from producing the GT?

Tom Scarpello, SVT Marketing and Sales Manager: I think clearly the greatest benefit is creating excitement around the Ford brand. It’s the kind of vehicle that 15-year-old boys will have posters up in their bedroom. It’s the kind of vehicle that you’ll lust after and dream about and if you’re lucky enough to see it on the road it will make an indelible impression on you. All of us who are car guys have those moments in our life. In a way, this is almost as much for the teenagers that are just starting to get really interested in cars — it will be, hopefully, part of their life and, long-term, make an impression on them. Maybe, really, the same way the GT40s did in the 60s for the guys who are buying the new GT now. You can call it image if you want. Although image almost sounds a little bit false. This is beyond image, its more kind of what you’re about, and having a vehicle like this kind of says what you’re about. We’re about fun and exciting vehicles. And, hey, if we can do this we can probably build a pretty nice vehicle for you to drive every day.

Primo Goffi, Product and Business Planning Specialist: In some ways we’re facing the naysayers, if you will, much like there were back in the early ’60s when Americans weren’t capable of building a Le Mans-winning car and all of the world championship cars came from Europe. In a lot of ways it’s history repeating itself. I know that’s been said many times but it rings loudly when supposedly the Americans weren’t capable back then and apparently there are a lot of people who feel like that today.

Alan Hall, SVT Communications Manager: I think a lot of people are expecting it to be of kit car type of quality and feel that anyone can throw a car together like that. That’s what’s going to wow people is the quality of the finished product after such a short development time.